Products

Contact us

Products

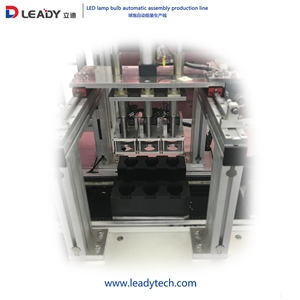

This automatic production line is developed for the lamp bulb in LED industry. It adopt to the segmented linear structure. The front part and back end of the line consists of automatic elevator collocation transmission which make up a chain ring linear vehicle lanes. The middle part uses sophisticated online rotary disk devices, which effectively reduces the footprint and space. Helped by artificial auxiliary implement to realize the high-efficiency semi-automatic production.

This Semi-automatic product line can apply to Lall kinds of LED bulb lamp. The inner structure need to be confirmed according to the products production flow. And the production capacity can be customized based on the customer's demands and products features.

Production flow:

The carrier lifter up

Manual install the heatsink

Manual dispense glue on heatsink

Manual install the driver and bulb base

Auto dispense glue on driver

Manual install and press the heat sink

Auto point heat conduction oil

Manual install the PCB board

Auto press the heat sink and PCB board

Auto soldering the soft wire

The carrier lifter down

Manual install the power board and bending the wire

Auto pull the soft wire

Auto cut the soft wire

Auto install the lamp cap

Auto cut the soft wire

Auto bend the soft wire

Auto install and press the nail

Auto rivet the lamp cap

Auto turn over the lamp base by 180 degree

Auto do the FCT testing and pick out the defective products

Auto dispense glue on lamp base

Auto install the bulb shell.

Specifications:

• Outline size:22500*2300*1600 mm(L*W*H )